PDF editing your way

Complete or edit your osha 300 log anytime and from any device using our web, desktop, and mobile apps. Create custom documents by adding smart fillable fields.

Native cloud integration

Work smarter and export osha form 300a directly to your preferred cloud. Get everything you need to store, synchronize and share safely with the recipients.

All-in-one PDF converter

Convert and save your osha 300a form as PDF (.pdf), presentation (.pptx), image (.jpeg), spreadsheet (.xlsx) or document (.docx). Transform it to the fillable template for one-click reusing.

Faster real-time collaboration

Invite your teammates to work with you in a single secure workspace. Manage complex workflows and remove blockers to collaborate more efficiently.

Well-organized document storage

Generate as many documents and template folders as you need. Add custom tags to your files and records for faster organization and easier access.

Strengthen security and compliance

Add an extra layer of protection to your osha 300 and 300a fillable forms by requiring a signer to enter a password or authenticate their identity via text messages or phone calls.

Company logo & branding

Brand your communication and make your emails recognizable by adding your company’s logo. Generate error-free forms that create a more professional feel for your business.

Multiple export options

Share your files securely by selecting the method of your choice: send by email, SMS, fax, USPS, or create a link to a fillable form. Set up notifications and reminders.

Customizable eSignature workflows

Build and scale eSignature workflows with clicks, not code. Benefit from intuitive experience with role-based signing orders, built-in payments, and detailed audit trail.

Award-winning PDF software

How to prepare Osha 300a

About Osha 300a

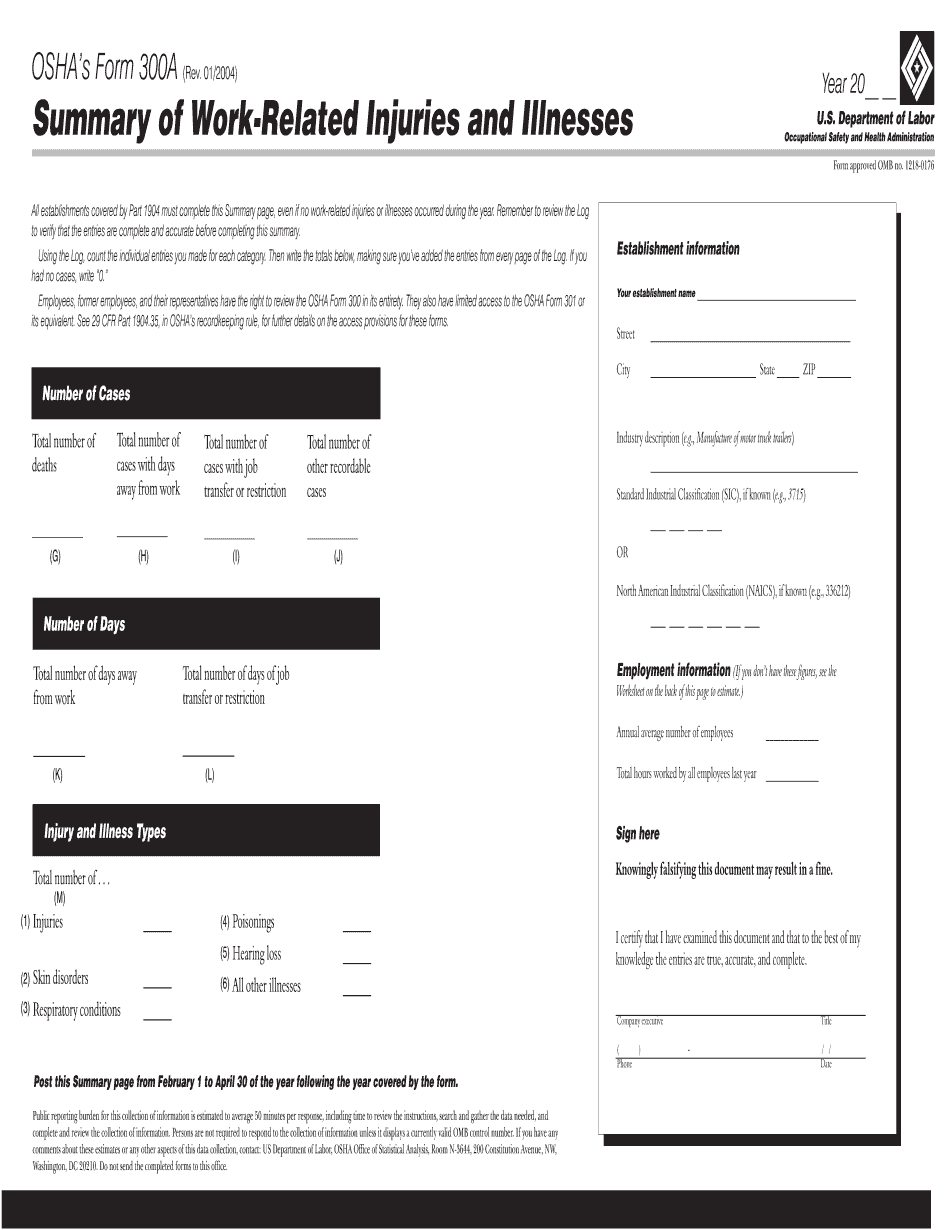

OSHA 300a is a form used by employers to report the number of workplace injuries and illnesses for a given year. It includes the total number of recordable cases, the number of days missed from work due to these cases, and the number of deaths that occurred on the job. The form must be completed and posted in a conspicuous location in the workplace from February 1st to April 30th of each year. OSHA 300a is required by the Occupational Safety and Health Administration (OSHA) for most employers with more than 10 employees in industries covered by OSHA. This includes employers in manufacturing, construction, healthcare, and many other industries. Additionally, some states have their own reporting requirements that differ from the federal standard, so it is important to check with your states regulations as well. Failure to comply with OSHA 300a requirements can result in hefty fines, so it is essential for employers to ensure they are meeting these requirements.

Prepare OSHA 300A Form

Companies and businesses who have ten and more workers have to keep comprehensive tracking of the injuries and health problems. Any job has its own risks. Throughout employment, a worker may get the physical injuries as well as mental types. The most frequent seem to be the repetitive psychological damages, falling objects damage, device and motor vehicle accidents. Those problems could be avoided, but nevertheless, lots of people in the US suffer from them every day.

The OSHA 300A template helps you to make statistics of the most frequently occurring issues and avoid them in the future. The example specifies all the conditions, damages along with a treatment cost. Any employee should fill in it carefully for an company and Occupational Safety and Health organization to know what activities to undertake.

Fill out the OSHA 300A form digitally in PDF and deliver it to your company. Applying this on-line option, the client usually spends less than a couple of minutes on the papers completion and will save time for further important organization.

Complete PDF Template Online

- Click on the 'Start now' button and adhere to such recommendations:

- Pick the “Text” tool and the box for info will appear. Place it inside the answer cell and put the necessary information.

- To add smart fields choose the “Add Fillable Field” choice and select the needed example. The date, number, signature, dropdown and checkbox and initials areas can be found here.

- After you have managed to write your PDF template, certify it with your signature. Set a officially binding signature right from the keyboard or maybe the touchpad.

- Save modifications by clicking on the “Done” button. After that, download the file towards the inner storage of your mobile phone or pc and send a digital OSHA 300A form or print out it on paper.

Online solutions help you to arrange your doc administration and supercharge the productivity of your particular workflow. See the fast details to be able to accomplish OSHA 300A, steer clear of errors and furnish it in a well timed manner:

How to accomplish an Osha 300A on the net:

- On the site with the template, select Start Now and go into the editor.

- Use the clues to complete the essential fields.

- Include your personal information and facts and contact data.

- Make sure that enter suitable details and numbers in appropriate fields.

- Cautiously proofread the content throughout the template also as grammar and spelling.

- Refer to the assistance section if you have any questions or ask our Support team.

- Set a digital signature on your Osha 300A with the help of the Sign Tool.

- When the template is completed, push Done.

- Send the completely prepared sample through e-mail or fax, print it out or save on your device.

PDF editor lets you make adjustments within your OSHA 300A from any on-line connected gadget, personalize it in accordance with your requirements, sign it electronically and distribute in various methods.

What people say about us

Gain access to professional submitting opportunities

Video instructions and help with filling out and completing Osha 300a